On-line monitoring systems in clean premises

To ensure permanent control of clean premises the Particle Measuring Systems company developed a range of automated solutions for implementation of on-line monitoring of air parameters, such as: Concentration of aerosol and microbiological particles, humidity, temperature, pressure.

Traditionally the main consumers of particle counters are pharmaceutical industry and micro-electronics. Implementation of particle counters in medicinal forms production is necessary, first of all, to ensure sterility and safety of final product. In accordance with GMP standards monitoring of particle concentration should be conducted constantly in clean premises of A and B classes and periodically – in C and D classes.

In the process of manufacturing of micro-electronic components the necessity of controlling of particle concentration is dictated by constantly increasing complexity of components themselves, as particles on their surface leads to big percentage of product deficiency, which is unacceptable in conditions of strong market competition. The Particle Measuring Systems company produces particle counters, which allow to built a full-scale system of control of particle concentration for almost any production.

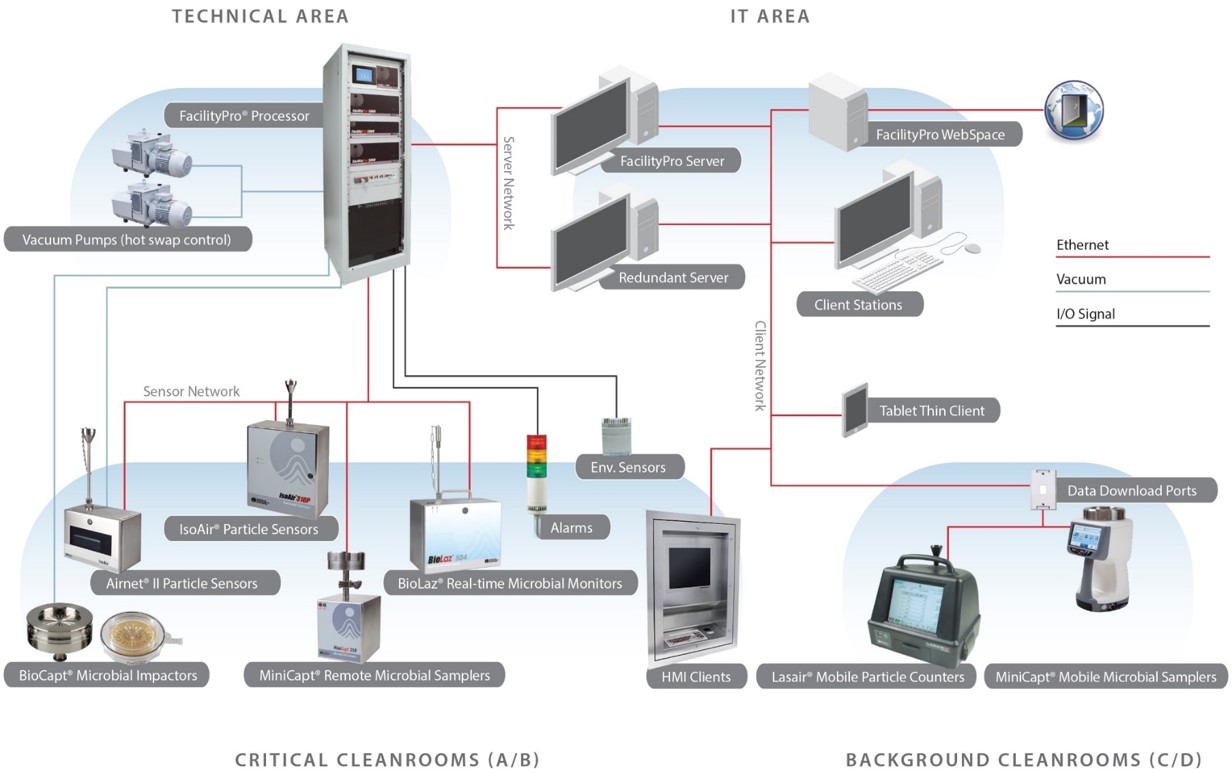

Continuous monitoring of pharmaceutical and other enterprises is usually conducted in several points at once, so it is impractical to use portable counters for this. Stationery sensors IsoAir (with a built-in pump) and a lightweight variation AirNet II (without a pump) allow to conduct continuous monitoring of particle concentration in fixed sampling points. They can be connected either to the computer, through the ENODE system or to the control system through the Facility Net industrial controller. The Particle Measuring Systems company has a huge experience of creating the systems of continuous control, where, apart from the particle counters, microbiological samplers, sensors of temperature, humidity and differential pressure are also installed, as well as some other sensors that the users need. Constructions with an external pump and different combs can be implemented within the systems, including the system of step-by-step sampling AM II 16/32, the system of data back-up and duplication of the main nodes. Different devices of human interface are built into the system, from signal towers and sound alarms to computer systems, designed specifically for clean premises.